Different types of springs and their scope of application

Tension springs : Tension springs, also known as compression springs or coil springs, are the most commonly used types of springs. They are usually coiled from wire and provide a restoring force when pulled or compressed lengthwise. Extension springs are used in a variety of applications, such as vehicles, furniture, electronics, and machinery.

Compression Springs : Compression springs, also known as compression springs, are springs that can be compressed and produce a restoring force when they return to their original position. They are often used in applications where shock absorption, suspension, or controlled compression is required, such as in the automotive, construction, medical, or appliance industries.

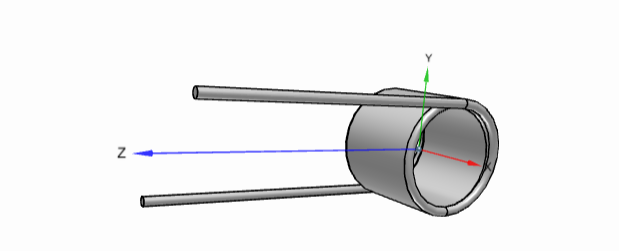

Torsion Springs : Torsion springs are springs that allow rotational movement and produce a restoring force when twisted. They are often used in applications where rotational movement, vibration damping or restoring force is required, such as in the watchmaking industry, metrology, toy manufacturing or electrical engineering.

Leaf springs : Leaf springs, also known as laminated springs or leaf spiral springs, consist of several metal strips connected together to provide flexible suspension. They are often used in applications where high load capacity, uniform suspension or shock absorption is required, such as commercial vehicles, agricultural equipment, construction or heavy industry.

Coil springs : Coil springs are helical springs that offer great elasticity and high spring force. They are used in various fields, such as in chassis, in shock absorbers, in industrial machinery or in medical technology.

Gas springs : Gas springs, also known as gas compression springs or gas compression dampers, use the pressure of gases to create controlled movement and restoring force. They are used in applications where smooth movement, load support or a locking function is required, such as in car doors, seating, folding tables or medical equipment.