What are standard parts?

Definition

Standard parts are standardized components that are used, for example, in the fields of mechanical engineering, electronics or technology. They are small parts that are manufactured according to specific standards – this ensures uniform dimensions, tolerances and performance characteristics. A distinction is made between international (ISO), European (EN) or German industrial standards (DIN). The designer does not manufacture the parts himself but purchases them from the manufacturer ready for installation.

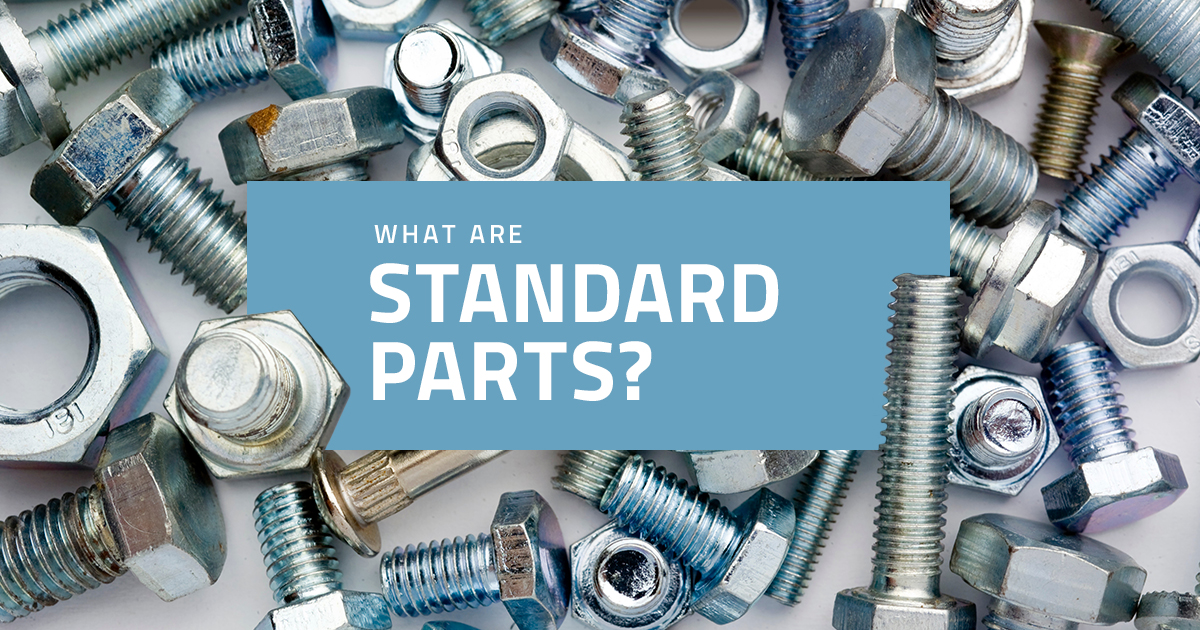

What standard parts are available?

Screws, rivets, nuts, washers, bolts or pins are often used, but the list of parts is long and the selection is large. To keep an overview and find the right components, manufacturers offer standard parts catalogs. The visual search engine 3Dfindit can be used to find standard parts from a wide range of manufacturers.

Where are standard parts used?

Standardized components can be used in all markets. In addition to the mechanical engineering, automotive, plant engineering, aerospace industry, research and development sectors, they are also used in the electronics industry and in construction.

What are the advantages of standard parts?

- Cost efficiency: Standardized components are often produced in large quantities, which means they can be offered at lower prices. Companies can additionally reduce costs for development and production of customized parts by using standard parts.

- Consistent quality standards: Through the established standards, the quality of the parts remains consistent and reliable.

- Time savings: By using standardized parts, companies do not have to spend time developing or validating custom components, so development and manufacturing time can be reduced.

- Faster time to market: By spending less time on the development and production of customized components, companies can respond more quickly to current market requirements and trends.

- Easy procurement: Standardized machine elements are offered by different manufacturers, so companies can optimize their supply chains and more easily acquire spare parts through different channels.

- Improved interoperability: The uniform standards facilitate the integration of components from different manufacturers, while at the same time promoting collaboration and the exchange of technologies between companies.

- Environmental friendliness: Because fewer customized components are needed, companies can reduce the amount of waste. In addition, standard parts are often easier to recycle or reuse.

- Simplified warehousing: Standardized dimensions and specifications enable both easier warehousing and inventory. Additionally, since companies no longer need to stock as many different parts, costs can be saved.

- International trade relations: By using standardized components that meet international standards, companies can be better integrated into global supply chains and establish trade relationships with partners in different countries.

Conclusion: Standard parts are an important component of modern industry and manufacturing – their use can be of great benefit: they help to increase the efficiency and quality of both products and processes and promote cooperation as well as trade on a global level. The increasing prevalence of standardized machine elements and the continuous development of norms and standards will continue to play an important role in the ever-changing global economy.